Our impact wrench test program is designed to provide a consistent reference standard to compare tool performance over time.

We also provide data for converting our tension readings into an approximate equivalent reading in foot-pounds because impact wrenches and pulse tools are usually rated in torque.

Conversion of tension to torque must be done with the following factors in mind:

- Accurate conversion of bolt tension readings to foot-pounds of torque must account for the dynamics of the friction between the threads and under the turned element. Tension developed in a bolt by the application of torque can vary greatly as the rate of rotation changes.

- The effective torque delivered by an impact wrench is related directly to the assembled joint stiffness. The same impact blow delivered to a hard joint will result in a different job torque than a soft joint. Tool performance as indicated on a tester may not equal the torque delivered to the job.

Our test bolt conversion factors have been established by tightening the bolt and nut continuously through it's working range at a fixed speed. Where the bolts are too large to test, we have used estimated factors based on the testing of smaller bolts.

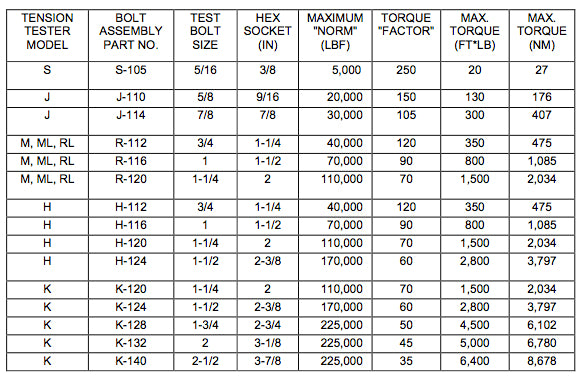

The following table describes the various test bolts, tension limits and approximating factors* which can be used to estimate the applied torque based upon the Skidmore-Wilhelm unit's gage (tension) reading. For reference, an approximate maximum torque for each test bolt is given.

Maximum capacity of the gage should not be exceeded.

* To estimate torque in ft-lb, divide gage reading of the unit by the factor. This will give an approximate equivalent in foot-pounds. Conversion is based on using S-W test bolt lube # R-0050. Components must be in good condition. Factors are best used in the midrange of the bolt's capacity. Note that testing torque does not equal torque on the application.